Level Measuring with F65 Series Ultrasonic Sensors

Ultrasonic technology for the right level

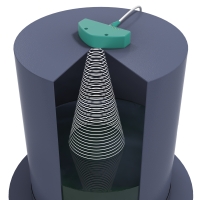

The F65 Series is available in three different measuring ranges for use in different container sizes

Level measuring is used in a wide variety of applications. The substance does not matter - ultrasonic technology detects almost all materials. Liquids like milk, chemicals, or lacquer, as well as mud or bulk goods are always controlled. Thus you can accurately monitor the fill level of silos or tanks used by dairies, chemical plants, mineral companies, and many others.

For level measurement in closed containers, F65 Series ultrasonic sensors are excellent. To detect liquid by using a sensor on the inside of a container, drill a 30 mm hole in the center of the container cap. Then mount the sensor with its special housing, including the gasket, directly on the container. The F65 Series is available in three different measuring ranges (6 cm … 50 cm, 20 cm …150 cm, and 25 cm … 250 cm) for use in different container sizes.

Different versions allow optimal adjustment to the application

The F65 Series comes in different versions for level measurement:

- with analog output for continuous fill level control, and additional switching output for overfill safety, or

- with two switching outputs for minimum and maximum fill level

For devices with two switching outputs (UCxxx-F65-E8R2-V15), the output Smax is dedicated to the maximum fill level (overfill safety) and the output Smin is dedicated to the minimum fill level (empty container).

The minimum switching point Smin can be taught via the input “XI”. With the tech adapter UB-PROG4-V15, this process gets even easier.

Simple setup and configuration

F65 Series can be easily installed on containers

For setup and configuration, the program interface 3RX4000-PF inclusive software “SONPROG for Windows” is available for all variants of the F65 Series.

To start, mount the sensor in the center of the container, so that the sound cone of the ultrasonic sensor does not reach the sides of the container and inadvertently detect the container’s own deposits or welds. Even the blind zone between the sensor head (white) and measuring range must be taken into account. Incorrect measurements can occur if the fill level is within the blind zone.

Ultrasonic technology impresses not only with its easy handling but also with its precision and reliability. Benefit from our know-how and control your fill level with Pepperl+Fuchs ultrasonic sensors.

Your advantages at a glance

- Reliable detection of liquids or bulk materials

- Continuous and accurate monitoring

- Overfill safety

- Easy subsequent sensor installation on containers

- Different versions for optimum adaptation to your application

PDF Downloads: Technology Guides Ultrasonic Sensors

Pepperl+Fuchs offers you various downloadable documents containing knowledge on ultrasonic sensors. In addition to a general technology guide on ultrasonic sensors, you can now download a new guide focusing on double material detection with ultrasonic sensors. Get your free PDF documents and benefit from valuable insights and advice for your field work!

+47 3557 3800

+47 3557 3800